In search of the appropriate balance: a definition of modular architecture

Thinking of architecture in terms of modules first poses the question of the appropriate balance. What are the right dimensions, the right proportions for man, for his way of life, for his body and his movements?

Modularity has long been at the heart of architectural thinking. As an abstract geometric framework or a set of simple, basic constructive elements to assemble, modular architecture sets the rules of the game for the architectural project, be it in in Palladian villas or in Japanese houses ordered by the precise arrangement of tatamis.

More recently, the modern movement and the acceleration of technological innovations in the twentieth century have offered new perspectives through the industrialisation of building processes. Standardisation and prefabrication therefore marked the production of the thirty-year post-war boom, at the risk of impoverishing architectural expression.

The challenges of carbon sobriety

Today, as the government prepares to implement the new RE2020 regulations in January, energy efficiency and the consideration of the carbon impact in the lifecycle of the materials are becoming more essential than ever in our architectural design. In light of these challenges of sustainable development, modular construction has many advantages.

In addition to the structure, prefabrication is used in many areas of construction, such as facades, bathrooms, and technical ducts. While reducing costs and saving time are the most obvious advantages, factory prefabrication also offers many benefits in terms of quality, sustainability, and resource management.

Quality control throughout the industrial process ensures a high-quality finished product. In hotels or accommodation, the prefabrication of bathrooms makes it possible to combine high-quality workmanship and time savings, since the prefabricated elements are produced in parallel to the site and then transported in-situ.

The industrial process offers more favourable conditions for the implementation of ethical materials (biosourced, recycled, local) and the new digital BIM tools allow for a greater synergy between designers and manufacturers for an optimised use of resources.

Thinking of the architectural project as an assembly of macro-elements also makes it possible to provide for the deconstruction and reuse of materials over the long term.

Modular architecture in the service of scalability

Together with Vinci Construction and Edeis, we recently responded to a consultation for the construction of military accommodation (classified E3 C1) throughout France.

Launched by the Ministry of Armed Forces, this call for tenders aimed to provide a uniform and standardised response to its growing housing needs. The challenge was to renew an aging housing stock and to make the military’s living environment more attractive.

The unprecedented nature of this consultation proved to be an opportunity for us to approach architectural design from a different angle, and to explore the potential of the “Habitat Colonne” constructive system that Vinci Construction has been developing for some years.

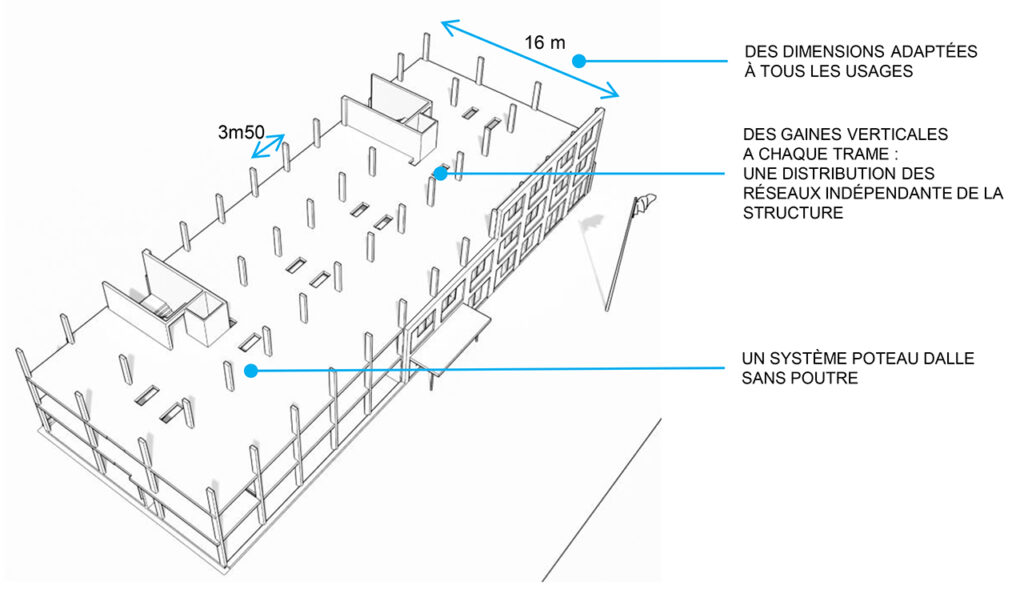

The army had structured its functional programme around the standardisation of spaces, and particularly of rooms. Each building was an assembly of modules of the same size (5m x 3m25) called “elementary spaces”. These modules also constituted a dense structural framework of slab-posts that freed us from beams and concrete walls and allowed for evolutions. The modules could accommodate different types of programmes (bedrooms, showers, changing rooms, offices, technical rooms, etc.) and were effectively interchangeable thanks to the design of the technical networks.

.

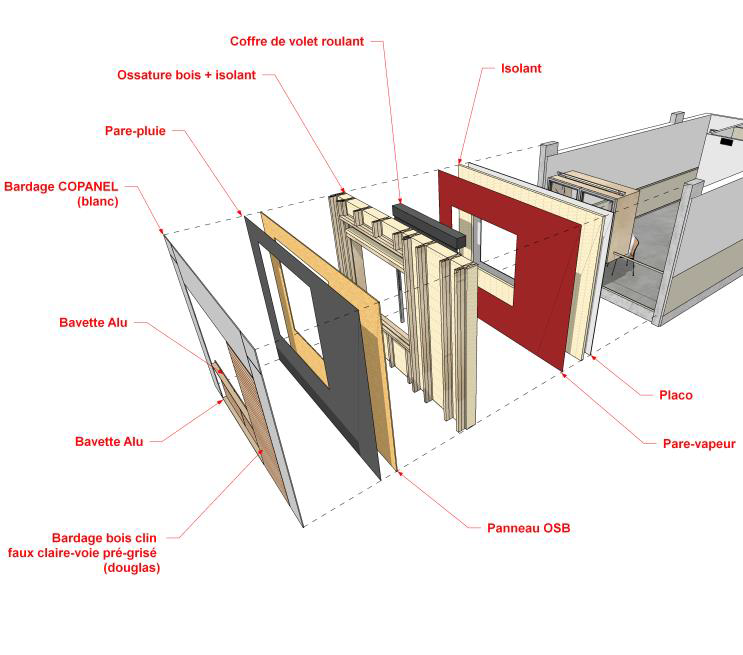

Off-site construction was strongly encouraged by the contracting authority, who wanted to minimise delays related to in-situ interventions. The team worked with Arbonis, a Vinci subsidiary specialising in wood construction, to develop the Wood Frame Facade System (FOB). The challenge was to imagine an off-site facade module that could be generalised throughout the building whilst expressing a strong identity and architectural quality that was consistent with the site.

.

{%CAPTION%}

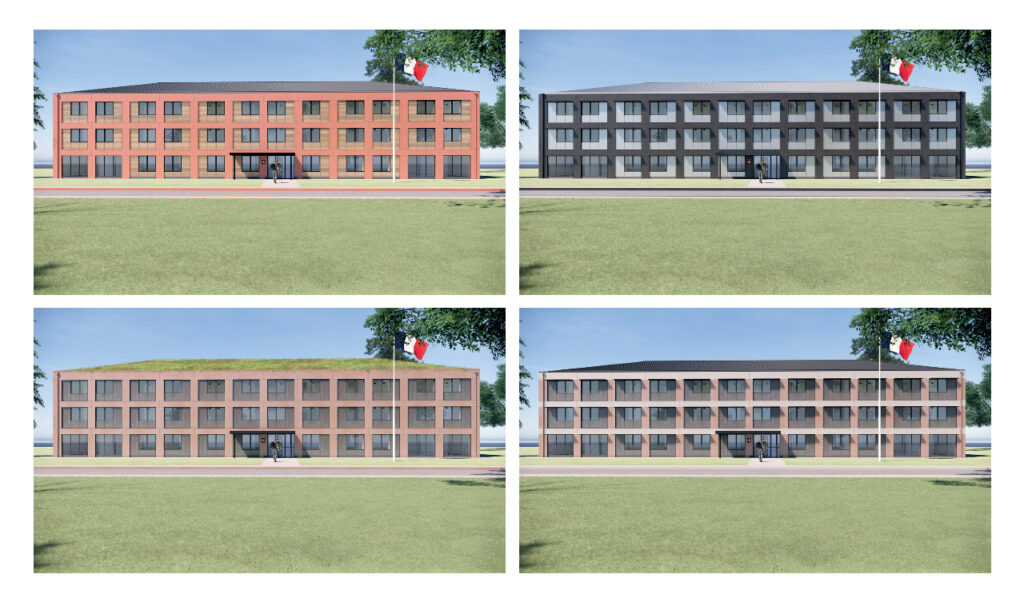

The thermal inertia was guaranteed by the concrete structure, whereas the envelope offered a very efficient and biosourced insulation. A set of options and finishes allowed us to adapt to the nature of the site (in the city, in the forest, in the suburbs, in the mountains, etc.), following a low-carbon approach to meet the Carbon 1 objectives of the E+C-. As with traditional construction, the modular construction allowed us to propose a great architectural diversity in our response.

In a changing world, where cities are evolving increasingly rapidly and unpredictably, the modular design opens up many fields of possibilities to combine reversibility, energy efficiency and low-carbon construction in our architectural creations.

-

Quentin Groslier Architect, Associate

TRAINING

École d’Architecture Paris- Villemin (received with the congratulations of the jury).

Graduation project: “Confronting urban risks: an emergency centre in peri-urban areas.”Languages: French – English